December 18, 2025

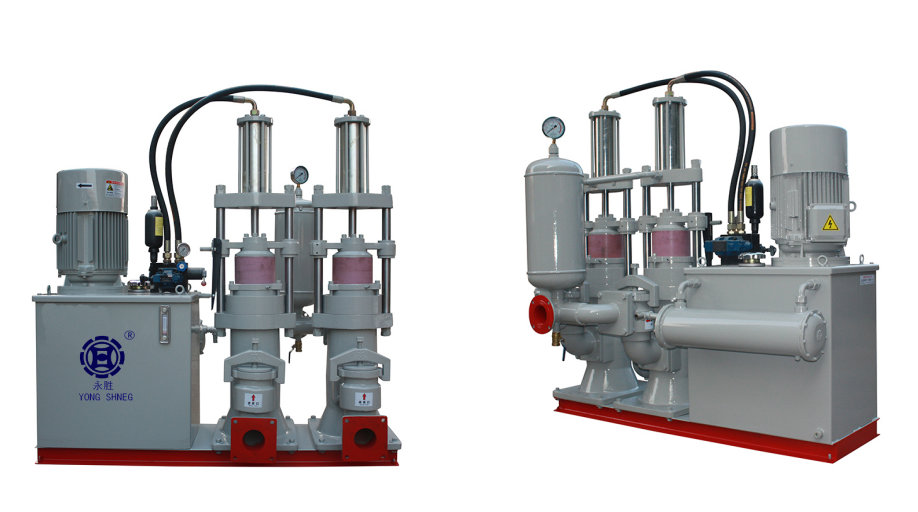

YB Ceramic Piston Slurry Pump

Piston Pump Usage:

- Matching with spraying silos for powder (Including ceramic, chemical and all the industries using spray gun).

- Pumping the slurry to filter presses (including washed kaolin, wastewater treatment, food and all the other solid liquid separation industries).

- Long transporting distance (200-1500m), or one pump aside several pools for slurry transport.

Piston Pump Working Principle:

YB series ceramic piston pump is hydraulic driven, Double-cylinder double-acting volume pump (vacuum pump).

This pump is driven by the motor, through the gear coupling to start up gear pump (referred to the oil pump), the oil pump suck low pressure oil from the tank and then discharge high pressure oil, through the valve, the high pressure oil is alternating into the two hydraulic cylinders, driving hydraulic cylinder pistons, then the pistons drives the two ceramic pistons (ceramic plunger) to reciprocate alternately, and the slurry is sucked and discharged through the pump inlet and outlet.

Reference about Pump Model Choice:

YB series piston pump is mainly used for transporting ceramic slurry, coal water slurry, kaolin and non-metallic mineral suspension liquid transportation. It is also used for the transportation of mine slurry, food suspension liquid, chemical slurry and magnetic material. The slurry pumped could be of more than 70 % solid content. What is more, variable frequency pump (variable flow pump) matching with filter press will be high efficient and save energy.

Attention for Choice:

- Check the slurry character, the slurry is not allowed to have big particles, otherwise it will cause pump work failure. If the slurry could not be polluted by iron, customer should choose the stainless steel plunger pump. For the acidic or alkaline slurry, customer should choose anti-corrosion plunger pump.

- Confirming the suitable flow range, the flow rate of pump is rated; customer should consider the suitable margin range for flow.

- Confirming the suitable pressure, the rated of the piston pump could reach 2.0Mpa. For matching with filter press, customers should choose variable flow pump (or variable frequency pump). For only transportation, customers should choose low pressure pump for saving cost and energy. After confirming the parameters, according to the principle of rather big than small, customer choose the pump according to the standard model.

- If any question, please call us, we will let our engineer to help you to choose the model.

Advantages:

- Anti-abrasion: ceramic piston is alumina ceramic firing, after grinding from fine, hardness HLC8.5 above, the surface roughness of 0.4um. Plungers will not break the slurry character, suitable for transporting the slurry containing sand and solid particles.

- Strong Suction: Piston and vacuum pump way, lift 0-6m (but the slurry character will also effect the lift).

- Adjustable constant slurry pressure and automatically variable oil flow: The pump working pressure could be adjustable within the range 0-20 kg. The adjusted pressure will not be changed due to the change of the pump discharge flow, it will be maintained, will not be changed even if its slurry discharge is shut off during pump running. (The flow change can not exceed the maximum flow, but the flow can be zero)

- High Pressure and High Efficiency: the maxi pressure of ordinary model is 20 kg. At the same pressure (≥ 5 kg) and same flow, this piston pump motor power is smaller than 1 to 2 model compared to other types of pumps.

- Easy Operation: tighten or relax the pressure regulating valve to adjust the pressure, then lock it tightly, no need to adjust in future.

- Low Usage Cost: the easy wearing parts are valve plate and water sealing. Normally, their change time is 3-6months, for Municipal sludge, their change be longer as 6-12 months.

- Usage Life: More than 15 years.

Model:

| 型号 Model | 额定流量 The rated flow (M³/h) |

压力范围Pressure range (Mpa) |

额定压力 Pressure rated (Mpa) |

冲程 Stroke (mm) |

电机功率 Motor powers power(KW) |

重量 Weight (KG) |

外观尺寸 Outline dimension LxWxH (mm) |

| YB85-3 | 3 | 0-2.0 | 1.8 | 220 | 4 | 600 | 1210X850X1500 |

| YB140-10 | 13 | 0-2.0 | 1.8 | 250 | 11 | 1100 | 1650x1050x1810 |

| YB200-19 | 19 | 0-2.0 | 1.8 | 250 | 18.5 | 1300 | 1800x1150x2050 |

| YB250-30 | 30 | 0-2.0 | 1.8 | 250 | 22 | 1650 | 2100x1450x2200 |

| YB300-40 | 40 | 0-2.0 | 1.8 | 250 | 30 | 1950 | 2050x1550x2200 |