July 11, 2025

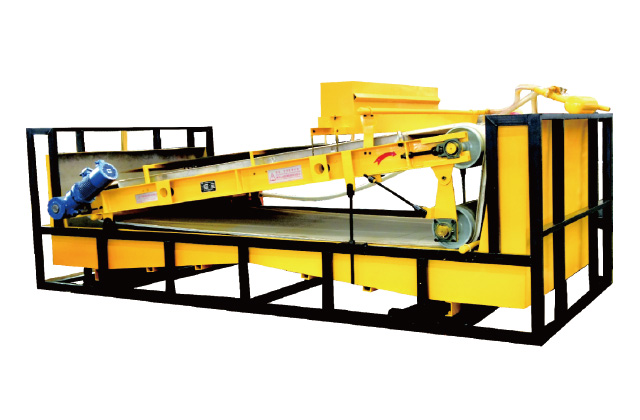

Wet High-Intensity Magnetic Plate Separator

What is a Wet Magnetic Plate Separator?

A Wet High-Intensity Magnetic Plate Separator is a specially designed separation equipment used to remove ferromagnetic and paramagnetic impurities from wet materials, especially slurry, mud, and liquid-based raw materials. It is widely used in industries like ceramics, kaolin, quartz, feldspar, metallurgy, chemical engineering, and non-metallic mineral processing.

This magnetic iron separator uses high-gradient magnetic technology, combined with plate-type structure, ensuring thorough separation of fine magnetic particles even under high-flow and low-density conditions.

How Does It Work?

The machine is equipped with strong neodymium magnetic plates, typically arranged in multiple layers. When the slurry flows through the separator, magnetic minerals are attracted and held by the plates, while non-magnetic materials pass through freely.

The system operates under a wet process, making it ideal for handling suspended or fluid materials. Once the separation is completed, the magnetic particles can be automatically discharged via a flushing mechanism, ensuring continuous operation and minimal downtime.

Key Features & Advantages

-

✅ Super Strong Magnetic Force: Adopts high-performance rare earth magnets (up to 17000 Gauss) for maximum efficiency.

-

✅ Optimized for Wet Materials: Designed specifically for handling slurry, liquid mud, and other moisture-heavy materials.

-

✅ Energy-Efficient Operation: Low power consumption with stable magnetic performance over long periods.

-

✅ Easy Maintenance: Modular design makes cleaning and maintenance super simple.

-

✅ Customizable Configurations: Plate size, magnetic intensity, and flow rate can all be customized to match different processing needs.

And let’s be real – if you’re dealing with fine iron particles in liquid, this thing’s gonna save your whole line from contamination problems.

Typical Applications

-

Ceramic Slurry Purification

-

Quartz Sand and Feldspar Processing

-

Kaolin Refining

-

Metallic and Non-metallic Ore Separation

-

Chemical and Food-Grade Material Purity Enhancement

No matter if you’re in a kaolin factory or processing quartz for high-end glass, this separator is your best bet to get rid of iron bits that ruin product quality.

Why Choose Jiangdong Machinery?

Jinjiang Jiangdong Machinery Co., Ltd. combines decades of magnetic technology innovation with advanced production capabilities. Located in Fujian, China, we supply cost-effective magnetic separators to global markets, with complete after-sales service and tech support.

Our Wet Magnetic Plate Separators have been exported to multiple countries and earned great feedback from users in ceramics and mineral industries.

Call to Action

Looking for a reliable magnetic separation solution for wet materials?

Talk to us today to get a quote, technical consultation, or custom design proposal.

Let’s help you keep your slurry clean and your product pure.