August 11, 2025

Three-Dimensional Vibrating Screen Separator

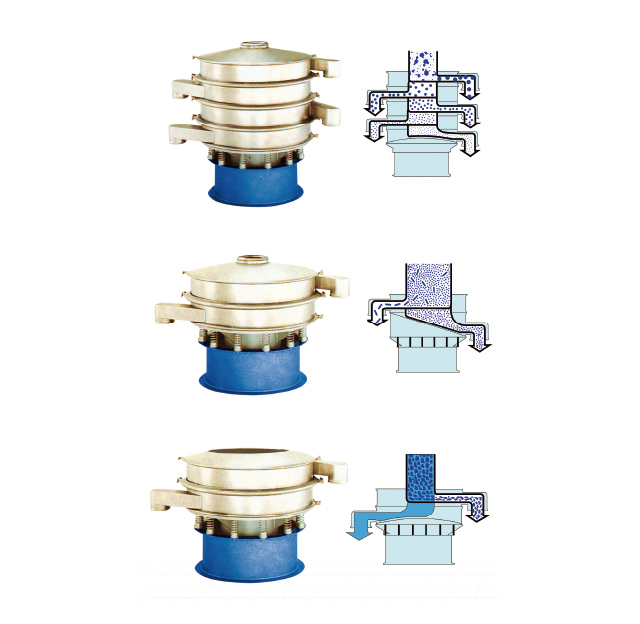

The Three-Dimensional Vibrating Screen Separator is a versatile, high-precision screening machine designed for efficient particle separation, grading, and filtering across a wide range of industries. With its unique vibration pattern and modular screen design, it can quickly classify materials into multiple sizes without compromising accuracy.

This equipment is suitable for dry powders, wet materials, slurries, and viscous substances, offering flexible mesh options, fast screen changes, and compact structure ideal for production lines with space constraints.

Key Features

-

✅ Quick Screen Change (5–10 Minutes): Innovative screen frame structure allows for easy and rapid replacement of fine meshes. Compatible with nylon, Teflon, PP and other mesh types.

-

✅ Compact & User-Friendly: Designed for easy handling and assembly—can be operated by a single person.

-

✅ Large Sieving Area & High Throughput: Compared with similar brands, this model delivers greater screening surface area and higher capacity for large-scale processing.

-

✅ Long Mesh Life, Low Cost: Fine mesh is fully supported by the base mesh, reducing breakage and extending mesh lifespan, which lowers long-term consumables cost.

-

✅ Accurate Particle Separation: Ensures even material distribution and uniform particle classification, preventing inconsistent granule sizes.

Let’s face it—nobody wants to waste time changing screens or reprocessing material due to size deviation. This unit just gets it done, clean and fast.

How It Works

The machine uses three-dimensional motion (horizontal + vertical + inclined vibration) to move material across multiple mesh layers. This movement maximizes material dispersion and separation efficiency. It supports multi-deck designs, allowing up to 5 layers of screening in a single pass, with up to 6 different output fractions.

Application Industries

This machine is engineered for broad industrial use, making it one of the most widely applicable screeners on the market:

🔬 Chemical Industry

-

Resin powder, pigment, soda ash, citric acid, silica, PVC, and micro-powders.

🏺 Ceramic & Mineral Processing

-

Lead oxide, quartz sand, glaze slurry, kaolin, refractory brick particles, abrasives.

🍬 Food & Beverage

-

Sugar, salt, milk powder, soy milk, yeast, carrageenan, baking powder.

📄 Pulp & Paper

-

Paper slurry, black/white liquid, coating materials, wastewater filtration.

🔧 Metallurgy & Powder Metallurgy

-

Zinc oxide, metal powders, electrode powder, calcium carbide, bone powder.

💊 Pharmaceuticals

-

Traditional Chinese medicine powders and liquids, Western medicine powders.

🌍 Environmental & Waste Management

-

Organic waste, waste oil, manure filtration, seafood processing waste.

Whether you’re refining powdered pharmaceuticals or separating glaze from ceramics, this screener helps ensure purity, consistency, and speed.

Why Choose Jiangdong Machinery?

Jinjiang Jiangdong Machinery Co., Ltd. is a trusted manufacturer of industrial screening and separation equipment. Our 3D vibrating screens are known for efficiency, reliability, and flexible customization across diverse industries.

With fast delivery, OEM support, and over 10,000 units in use worldwide, we’re here to help streamline your screening process.

Call to Action

Looking for a multi-layer, high-precision sieving solution that’s easy to use and built to last?

Contact Jiangdong Machinery today for spec sheets, pricing, or a customized quotation.

Let’s screen smarter—faster—and more profitably.