July 16, 2025

Drawer-Type Magnetic Separator for Powder (Cabinet-Type Iron Remover Accessories)

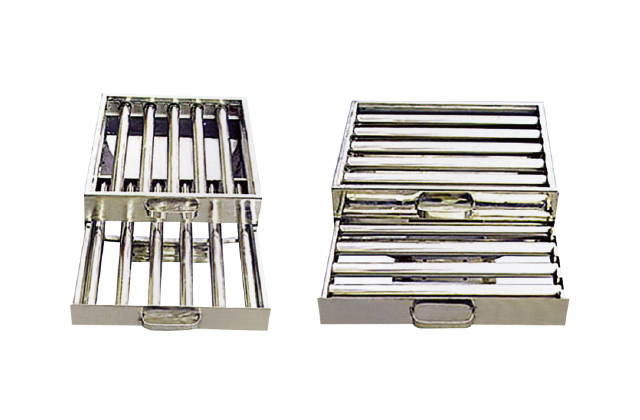

The Drawer-Type Magnetic Separator is a cabinet-style magnetic filtering unit designed for the continuous removal of ferrous impurities from fine powder materials. It is equipped with multiple layers of high-intensity magnetic bars (up to 10000 Gauss) arranged in a compact, efficient layout, ensuring thorough filtration without interrupting production.

Perfectly suited for ceramic raw materials, quartz sand, kaolin, feldspar powder, silicon carbide, and other dry flowable powders in the chemical, plastic, and food industries, this system allows inline installation with minimal maintenance.

Key Features

-

✅ High Magnetic Strength: Uses powerful neodymium magnets rated at 8000GS or 10000GS, enabling the capture of even ultra-fine ferrous contaminants.

-

✅ Tri-Layer “Pin”-Shaped Arrangement: Magnetic bars are installed in a staggered, three-layer formation to ensure materials flow across multiple separation stages, significantly improving iron removal efficiency.

-

✅ Uninterrupted Operation: While one magnetic layer is being pulled out for cleaning, raw material feeding continues uninterrupted, making it ideal for automated or continuous production lines.

-

✅ Modular & Replaceable: Magnetic rods are easy to remove and clean. Customizable cabinet dimensions and magnetic layouts are available to suit specific production needs.

-

✅ Hygienic Stainless Steel Design: Made with SUS304 stainless steel, safe for use in food-grade or corrosive environments.

Technical Specifications

| Parameter | Value |

|---|---|

| Production Capacity | 2–5 tons/hour |

| Magnetic Strength | 8000GS / 10000GS |

| Magnetic Rod Spec. | Φ25 × 300 mm |

| Rod Spacing | 25 mm |

| Rod Count | 17 or 33 rods |

| Rod Layers | Tri-layer “Pin”-shaped structure |

| Outer Dimensions | 450×450×1000/1200 mm 450×450×350/550 mm |

| Custom Options | Available for size, layer count, inlet/outlet type |

Note: Additional sizes, discharge hoppers, or flange configurations can be customized based on installation environment.

Application Scenarios

🏺 Ceramic Materials

-

Iron removal from feldspar powder, kaolin, quartz sand, frits, and oxides.

🧪 Chemical Industry

-

Purification of resins, pigments, metallic powder, or abrasive materials.

🍬 Food Industry

-

Elimination of ferrous particles from flour, starch, cocoa, and food additives.

🧴 Plastic & Polymers

-

Used in plastic pellet and powder production lines to ensure impurity-free mixing.

Installation & Usage

The unit can be directly mounted between gravity-fed pipelines, feed hoppers, or conveying chutes. Magnetic rods are manually or pneumatically pulled out for scheduled cleaning, and operators can clean them without halting production.

The layered magnetic arrangement ensures even powder distribution and maximizes exposure time for magnetic separation.

Why Choose Jiangdong Magnetic Accessories?

At Jinjiang Jiangdong Machinery Co., Ltd., we build magnetic separators that are not only efficient but also user-friendly and production-ready. Our drawer-type magnetic cabinet is ideal for medium to high-throughput applications, offering durability, customizability, and stable magnetic performance for up to 8 years.

We provide technical drawings, OEM services, and fast overseas shipping.

Call to Action

Need a high-capacity magnetic separator for powder line automation?

Contact Jiangdong Machinery today to request technical specs, 3D models, or a tailored quotation for your processing line.