July 16, 2025

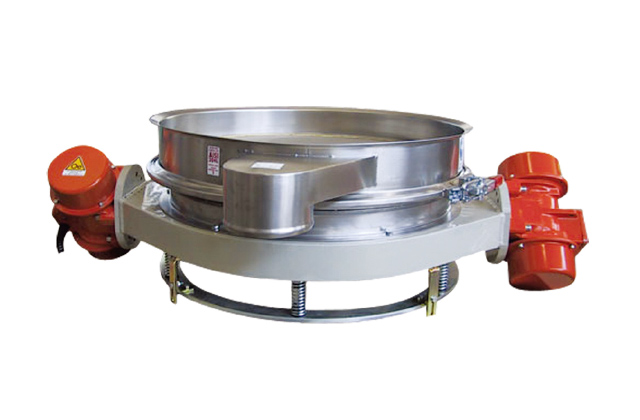

Direct Discharge Vibrating Screen (Inline Vibro Sifter)

The HX Series Direct Discharge Vibrating Screen is a specially engineered inline sieving solution designed for bulk material handling, continuous production, and spatially constrained environments. This upgraded model utilizes dual vibration motors as its source of excitation, enabling central feeding and central bottom discharge—ideal for streamlined integration into automated systems.

If you’re operating under tight installation conditions or dealing with high-throughput lines, this machine keeps things moving—literally and efficiently.

Key Features

-

✅ Compact & Simple Design: The machine features a straight-through structure with minimal parts, making it easy to install, clean, and maintain.

-

✅ Customizable Vibration Settings: Adjustable vibration amplitude and excitation force, allowing flexible tuning for different material characteristics.

-

✅ Perfect for Inline Operation: The top feed-to-bottom discharge configuration enables continuous, large-batch operation, with no bottlenecks.

-

✅ Space-Saving Build: Designed to operate without restrictions on height or floor space, ideal for tight workshops or layered machinery systems.

-

✅ Low Noise, High Stability: Quiet operation and strong vibration ensure long-term stable screening performance—even in 24/7 production.

It’s the kind of machine that doesn’t make a fuss—it just gets the job done behind the scenes, shift after shift.

How It Works

Material is fed from the center inlet at the top of the machine. As it reaches the vibrating screen deck, the dual motors generate horizontal and vertical motion, causing particles to disperse, stratify, and pass through the screen.

Qualified material passes through the mesh and is directly discharged from the center bottom outlet, ensuring minimal transfer time and ideal flow-through performance.

Applications

The Direct Discharge Vibrating Screen is optimized for bulk and inline screening across a variety of industries and materials, including:

🧪 Chemical Industry

-

PVC powder, paint, silica, catalysts, resins, pigment.

🍬 Food Industry

-

Sugar, salt, starch, flour, milk powder, cocoa powder.

⚙️ Metallurgy & Ceramics

-

Quartz sand, alumina, oxides, abrasives, refractory powder.

💊 Pharmaceuticals

-

Bulk raw powders, herbal extracts, excipients.

📄 Paper & Slurry

-

Coating material separation, paper pulp filtering.

Especially useful in setups where space is tight or inline flow is mandatory, this model integrates easily with silos, pneumatic conveying lines, or production conveyors.

Why Choose Jiangdong Machinery?

Jinjiang Jiangdong Machinery Co., Ltd. delivers cost-effective and high-performance screening equipment built for industrial reality—where space is limited, volumes are high, and downtime is expensive.

Our HX series inline sifters have been adopted by clients across chemical, food, and materials processing industries for their modular design, stable output, and easy integration.

Call to Action

Running out of space on your production line? Need an inline sieve that keeps up with volume?

Reach out to Jiangdong Machinery today for detailed specs, pricing, or a custom layout proposal.

We’re here to help you screen smarter, not harder.