August 14, 2025

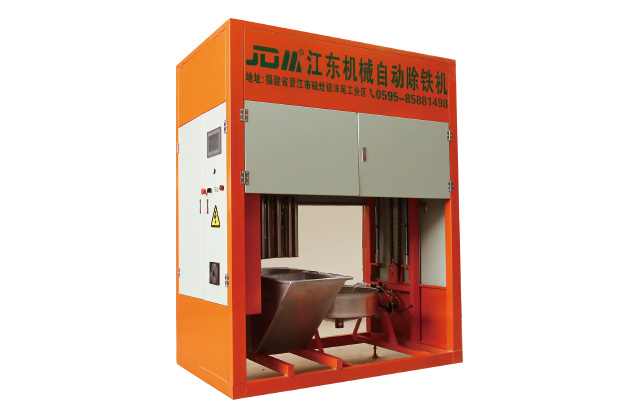

Automatic Permanent Magnetic Slurry Separator (Rod Type)

The Automatic Permanent Magnetic Slurry Separator, also known as the Magnetic Rod-Type Iron Remover, is specially engineered for the efficient removal of fine, weakly magnetic impurities from various slurry-based materials. With its advanced automatic operation and high-intensity magnetic core design, it delivers unparalleled separation performance—perfect for high-volume, industrial applications.

Whether you’re working in metallurgy, abrasives, ceramics, or chemicals, this fully automated system is built to keep your materials clean and your process smooth.

How It Works

This equipment uses first-generation imported high-strength magnetic cores, which generate an ultra-strong magnetic field with a gradient effective up to 150mm, nearly 10 times stronger than conventional magnetic systems.

Depending on your process, you can choose between 4 to multiple magnetic rods inside the unit. These rods rotate in both forward and reverse directions continuously, maximizing the contact time with slurry and improving the iron removal rate.

Even better – the entire system runs automatically:

Iron capturing, demagnetization, and cleaning are fully automated, which means:

👉 No manual handling,

👉 Minimal downtime,

👉 Super high efficiency.

Key Features

-

✅ High Magnetic Field Strength: Equipped with rare earth magnets (above N48H grade) with temperature tolerance up to 100°C, extending magnetic core life to 5–8 years.

-

✅ Multiple Magnetic Rod Design: From 4 rods to customized configurations to match high throughput needs.

-

✅ Dual-Direction Rotation: Ensures full powder absorption and cleaner output.

-

✅ Automated Cleaning: Fully automatic demagnetization and rinsing—no operator required.

-

✅ Robust and Durable: Engineered for continuous industrial operations with minimal maintenance.

Honestly, once you switch to this fully auto design, you’ll never wanna go back to manual systems again.

Typical Applications

The machine is ideal for removing fine weak magnetic substances from various slurry materials in:

-

Metallurgy & Mining

-

Abrasive Materials

-

Ceramics Production

-

Chemical Slurry Filtration

-

Non-metallic Mineral Processing

Whether it’s iron contamination in kaolin, glaze slurry, or chemical suspensions, this separator does the job cleanly and reliably.

Why Choose Jiangdong Machinery?

At Jinjiang Jiangdong Machinery Co., Ltd., we’re not just making machines—we’re solving problems. With advanced R&D, precise processing equipment, and a nationwide service network, we deliver cost-effective magnetic separation solutions trusted across China and beyond.

Our Automatic Magnetic Rod Slurry Separator is already helping manufacturers in ceramics and mining reduce downtime, improve product purity, and cut labor costs.

Call to Action

Need an automatic slurry iron remover that works harder and lasts longer?

Contact Jiangdong Machinery now for a custom quote, technical drawing, or free consultation.

Let us help you upgrade your separation system today!